- home

- blog

- in-depth learning

- size does matter - the benefits of high output torque

size does matter -尊龙凯时网址

as per feedback from customers around the world, we noticed that ultra-high rigidity and ultra-high torque planetary speed reducers are required by machine tool manufacturers. unfortunately most planetary gearboxes makers do not offer such products and even no alternatives available. the following is an introduction to this gray area that few industry people have focused on, and what traditional limitations of planetary gearboxes have we broken through.

options for motors and gearboxes (speed reducers)

there are two types of planetary gearboxes. one is the planetary gearboxes used with traditional induction motors. they are mainly used for power transmission, and precision is not necessary. the other is planetary gearboxes that are used with servo motors. it is very particular about positioning accuracy and torque control, which is so called motion control.

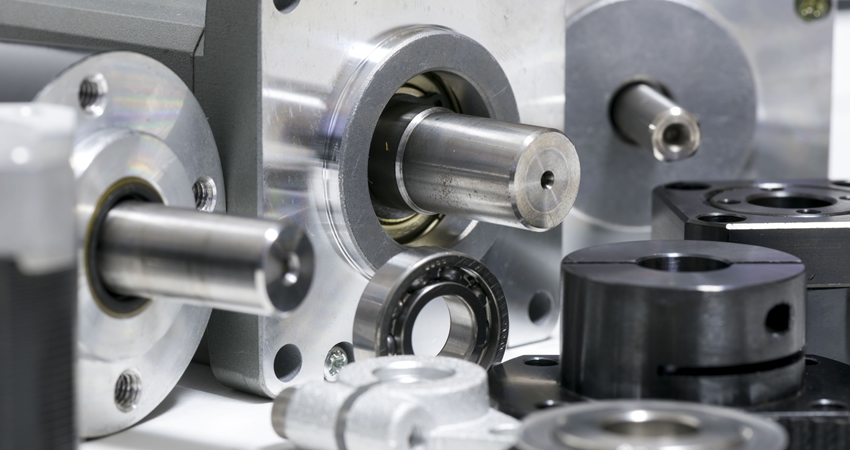

what is a planetary gearbox?

"planetary gear system" is composed of a sun gear, planetary gears, ring gear and planetary arm carrier. it has the characteristics of small size, light weight, high transmission efficiency, and large load capacity. compared with the traditional speed reducers, the servo motor planetary speed reducers (or gearboxes) can achieve the benefits of high efficiency and compact design of gear transmission. the frame size of the planetary gearboxes for servo motors can be divided from 115 mm. frame size 115 mm or smaller (approximately for output 3kw motor) is a small and medium size, mainly applied to automation. precise positioning, low backlash, low noise are required. medium and large frame sizes are 142 mm or larger (for motors output above 5kw) are used in the field of machine tools.

typical restrictions of planetary gearboxes

the main market of servo motor planetary gearboxes is industrial automation and small or medium size gearboxes are used. most of the planetary gearboxes manufacturers produce 115 frame size or smaller ones. large size gearboxes are available only by frame enlarged without rigorous engineering, and ignoring that the demand for rigidity and backlash will be higher when using medium and large frame size planetary gearboxes. if the gearbox is not rigid enough and twisted under high torque loading, it will produce a spring damping effect in the transmission chain, causing the driven parts (such as turret or column) to oscillate back and forth. in addition to delaying the processing time, it may also cause potential problems such as inaccurate machining accuracy and even tool collision. however, due to the relatively less sales of medium and large-sized gearboxes, long lead time, high cost and low inventory turnover, such gearboxes will not be specially developed. therefore, it is difficult for machine tool builders to fully introduce planetary gearboxes in powertrain.

typical solution and dilemma

when the machine tool builders are facing both high-horsepower transmission and precise positioning requirements, it is a dilemma to select planetary gearboxes. although a large speed reducer with sufficient rigidity for high power transmission fits require, usually backlash performance is not good enough. if they take a servo motor planetary gearbox with high positioning accuracy, the rigidity and allowable torque cannot meet the requirements of the machine tool builders, which may be damaged in a short time, causing additional service cost and brand reputation damage.

advantages of sesame planetary gearboxes

sesame motor works with machine tool manufacturers to tailor made two gearbox products for large-scale machine tools or special-purpose machines. in addition to the original low backlash, low noise and other servo motor planetary gearbox characteristics, they also have ultra-high rigidity and ultra-high toughness. so that the users do not need to choose between rigidity and precision, the two requirements (rigidity and precision) are met at one time. no dilemma from now on.

planetary gearboxes with ultra-high rigidity and toughness features

the gearbox will not be twisted or deformed and no vibration under high torque loading and emergency stop condition. the turret processes immediately wherever it goes without waiting to meet the needs of machine tool customers. the robust design is a great benefit to retains low backlash, low noise and other planetary gearbox characteristics when receiving the challenges of harsh environment such as extreme hot and cold.

conclusion

sesame motor professional r&d team and flexible manufacturing department are willing to solve tricky problems or applications. therefore, most of the cooperation between sesame and our customers started from engineering rather than back-end procurement. we took on this challenge that the customer identified as unsolvable, and developed an ultra-high rigidity and toughness planetary gearbox to offer a solution of rigidity, torque, precision, backlash and cost issues. we believe customers' success depend on our continue innovation and offering of flexible and competitive solutions to meet the requirements of industry development.

►►►[contact us now] sesame representatives are willing to offer the best solutions.