induction motors are the most common type of electric motors on the market due to their simple structure, relatively low manufacturing costs, and stable operation by supplying easy access ac power. the following content briefly explains the operating principles, types and common applications of induction motors.

how does an induction motor work?

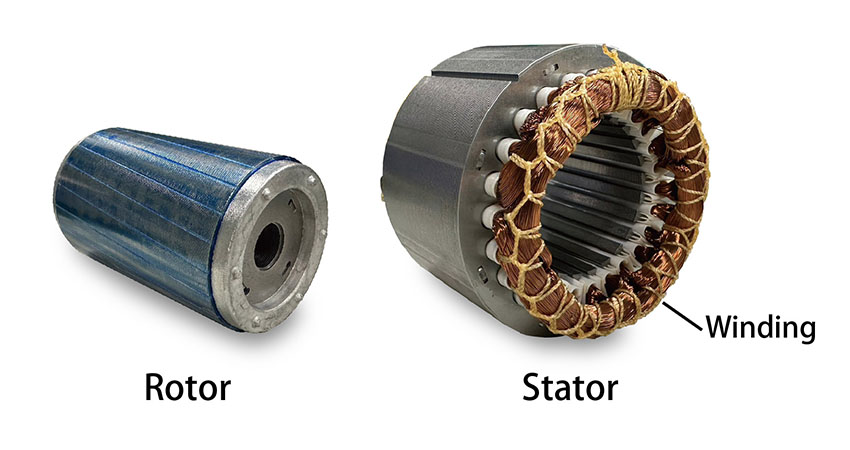

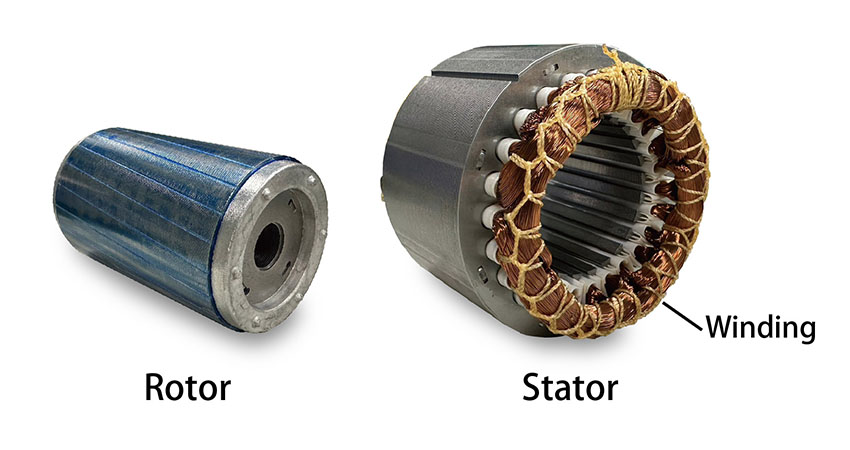

induction motors are electric motors that rotate due to magnetic field induced by supplying alternating current (ac) to convert electricity into mechanical output. the basic structure that generates electromagnetic induction in an induction motor consists of a fixed stator and a rotating rotor. a stator consists of a laminated core and coils of insulated wire known as the windings. a rotor consists of laminated steel or conductive material to facilitate the generation of induced current. there is an actual physical gap known as air gap that separates the rotating rotor and the stator. the principle is:

- the ac power supplied to the motor's stator creates magnetic fields.

- the stator's magnetic field induces an opposing current in the rotor.

- the induced currents in the rotor in turn create magnetic fields.

- the rotor's magnetic fields interact against the stator's magnetic fields and cause rotor rotation.

〈

read more:

choosing motor basics: types of ac motors & dc motors〉

types of induction motor

induction motors are categorized into two main types according to ac power supplied: three-phase and single-phase induction motors.

tree-phase induction motors

there are three sets of symmetrically distributed coil windings in the stator of a three-phase induction motor. when three-phase ac power is supplied to the coil windings, the rotating magnetic fields with the same frequency as the ac power will be generated to drive the rotor.

single-phase induction motors

the stator contains a primary winding and an auxiliary winding. the main winding is designed to produce a magnetic field when an ac power is applied. the auxiliary winding is used to create a rotating magnetic field.

comparison of three-phase and single-phase induction motor

| |

three-phase induction motor |

single-phase induction motor |

| ac power |

three-phase |

single-phase |

| starting mechanism |

self-starting |

require auxiliary starting winding or startup capacitor |

| efficiency |

high |

low |

| structure |

more complicated |

easy and simple |

| maintenance |

difficult to repair |

easy to repair |

| applications |

industrial, machinery and commercial drives |

domestic appliances with lighter loading |

structure of induction motors

the internal structure of the induction motor is mainly composed of a stator and a rotor. other components include a motor casing, a cooling fan, etc. the main structure of the stator is an iron core composed of stacked thin silicon steel plates and coil windings. the main structure of the rotor is a core composed of laminated steel sheets or cast by aluminum, a motor shaft and bearings. there are two designs for the rotor in an induction motor: wound rotor and squirrel cage due to different rotor structures. squirrel cage rotor simple, rugged and low maintenance costs construction make squirrel cage induction motors the favorite for mass production and most applications.

squirrel cage rotor

the squirrel cage motor rotor is a cylindrical steel lamination core mounted on a shaft. internally it contains longitudinal conductive bars (usually made of aluminium or copper) set into grooves and connected at both ends by shorting rings forming a squirrel-cage-like shape.

wound rotor

a wound rotor’s design is more complex than that of a squirrel cage rotor. in addition to a laminated iron core, there are three-phase windings connected to slip rings mounted on the rotor shaft. brushes are in contact with these slip rings, providing an external connection for delivering electricity to the wound rotor.

where are induction motors used?

induction motors are widely used in various fields, where it is for domestic or industrial use, because of their characteristics of simple structure, low cost and easy maintenance.

household appliances

single-phase induction motors are often used to drive various devices for domestic purposes in household appliances. these devices include fans, air conditioners, hair dryers, vacuum cleaners, refrigerators, ventilators, rolling doors, treadmills, water pumps, etc. for example:

- a single-phase induction motor might be used to power blades or fans to rotate and cause air flow to achieve the functions of air supply and exhaust in electric fan, hair dryer, ventilator, and vacuum cleaner.

- a single-phase induction motor might be used to drive the compressor inside air conditioner and refrigerator.

- a single-phase induction motor is used in the treadmill to drive the rollers and running belt.

- a single-phase induction motor combined with a gear reducer, brake, control circuit and other components to drive the rolling door.

- a water pump basically consists of a motor and a pressurizing pump. the motor provides the power source for the pump to pressurize.

commercial appliances

many commercial equipment use induction motors as the power source in various business premises. for examples, escalators, key cutting machines, cup sealing machines, ice cream machines, barrier gates, water pumps.

- the induction motor provides the rotating force and work with a speed reducer to transmit the high rotational speed of the motor into the slow, high-torque motion needed to drive the escalator.

- in a key cutting machine, the primary function of an electric motor is to provide the rotational power necessary for cutting and duplicating keys.

- induction motors are used with speed reducers in cup sealing machine to move cups, containers and sealing head at a controlled speed.

- a small fractional horsepower ac induction motor drives the rotating dasher/agitator blade that churns and aerates the ice cream mix during freezing. larger ac induction motors, usually 1-2 hp or more, are used to drive the compressor for the refrigeration system that freezes the ice cream mix.

- a fractional horsepower ac induction motor provides the rotational force to raise and lower the boom arm through a gearbox or chain/belt mechanism.

- in a water pump, the primary function of an induction motor is to provide the mechanical power required to drive the pump impeller or mechanism that moves the water.

industrial applications

three-phase induction motors are used to drive various machines and equipment for manufacturing purposes. these machines and equipment include lifts, conveyors, exhaust fans, grinding machineries, carton sealers, label machineries, mixers, food processing machineries, packaging machineries, etc. for example:

- the primary function of induction motors in industrial lifts is to provide the necessary torque and power for lifting and lowering the lift car or platform. these motors are typically connected to a gearbox or traction system that converts the rotational motion into linear motion for moving the lift car up and down.

- driving the conveyor belt or chain: the most fundamental function of induction motors in conveyors is to drive the conveyor belt, chain, or other material handling mechanism. the motor's rotational power is transmitted through a gearbox, pulley, or direct drive to impart linear motion to the conveyor.

- ac induction motors are used to directly drive the fan impeller or blades, providing the rotational force required to move air or gases.

- induction motors are used to drive the grinding wheel or spindles, providing the high-speed rotational force required for grinding operations.

- induction motors are commonly used to drive the conveyor belts that transport the cartons through the sealing process in a carton sealer.

- induction motors are used for driving the conveyor belts that transport the products through the labeling process, as well as for powering other mechanical components like label rewinders or unwinders.

- induction motors combined with speed reducers are widely used in mixers to drive the mixing shaft or impeller, providing high torque rotational force required at relatively low speeds for mixing or agitating the materials.

- induction motors or gear motors are widely used in food processing machinery. they are used to power the conveyor belts that transport food products through various stages of processing, such as sorting, washing, cutting, or packaging. to provide the rotational force required to drive the mixing shafts or impellers in mixers, blenders, and other mixing equipment used for combining ingredients or homogenizing food products. induction motors or gear motors are employed to drive pumps for liquid handling, such as transferring liquids or slurries, and to power fans for ventilation or pneumatic conveying systems. they are also used to operate various food processing machinery, such as slicers, dicers, grinders, extruders, and packaging machines, providing the necessary rotational power for their operations.

- both induction motors and gear motors are commonly used in packaging machinery, providing different functions depending on the specific requirements of the packaging process. for example, conveyor belts are driven to transport packaging materials or finished products during various stages of the packaging process, such as filling, sealing or labeling. they provide the rotational power required to operate a variety of packaging machines, such as form-fill-seal machines, cartoners, case packers, palletizers, and wrapping machines. in packaging lines, induction motors are used to drive fans or blowers in air circulation, cooling or pneumatic conveying systems. in addition, in some packaging processes involving liquid filling or handling, induction motors will also provide power for pumps to transport liquids or slurries. induction geared motors are typically used in applications that require high torque at relatively low speeds, such as driving rotary sealing mechanisms, capping machines or intermittent motion mechanisms used in packaging operations.

conclusion

induction motors operate by being supplied with ac power, which is readily available in homes, commercial premises, industrial and manufacturing sites. therefore, induction motors currently have the highest market share. in addition, the rotation speed and output torque characteristics of induction motors vary depending on size, appearance, coil winding conditions, rotor material, manufacturing method, etc., so they have the widest range of applications. sesame motor has more than 30 years of manufacturing and sales experience of induction motors, gear motors and speed reducers. the products are not only 100% made in taiwan, but also ce, ul, and ccc certified, marketed in more than 50 countries around the world. we can meet your all-round application from basic power transmission to highly dynamic motion and precise control, assist you in choosing the most suitable product, and can customize it according to your needs.

contact sesame motor.